One of the major projects in my CAD and fabrication course (MCEN 1025) was to manufacture a working wobbler engine that could run at 15 psi for at least 1 minute.

For some background, a wobbler engine is a simple steam engine which is also known as an oscillating cylinder steam engine. Our version was composed of 16 different components, 6 of which were fabricated using various methodologies. The parts fabricated include:

Base Plate

Valve Plate

Cylinder

Piston

Crankdisk

Flywheel

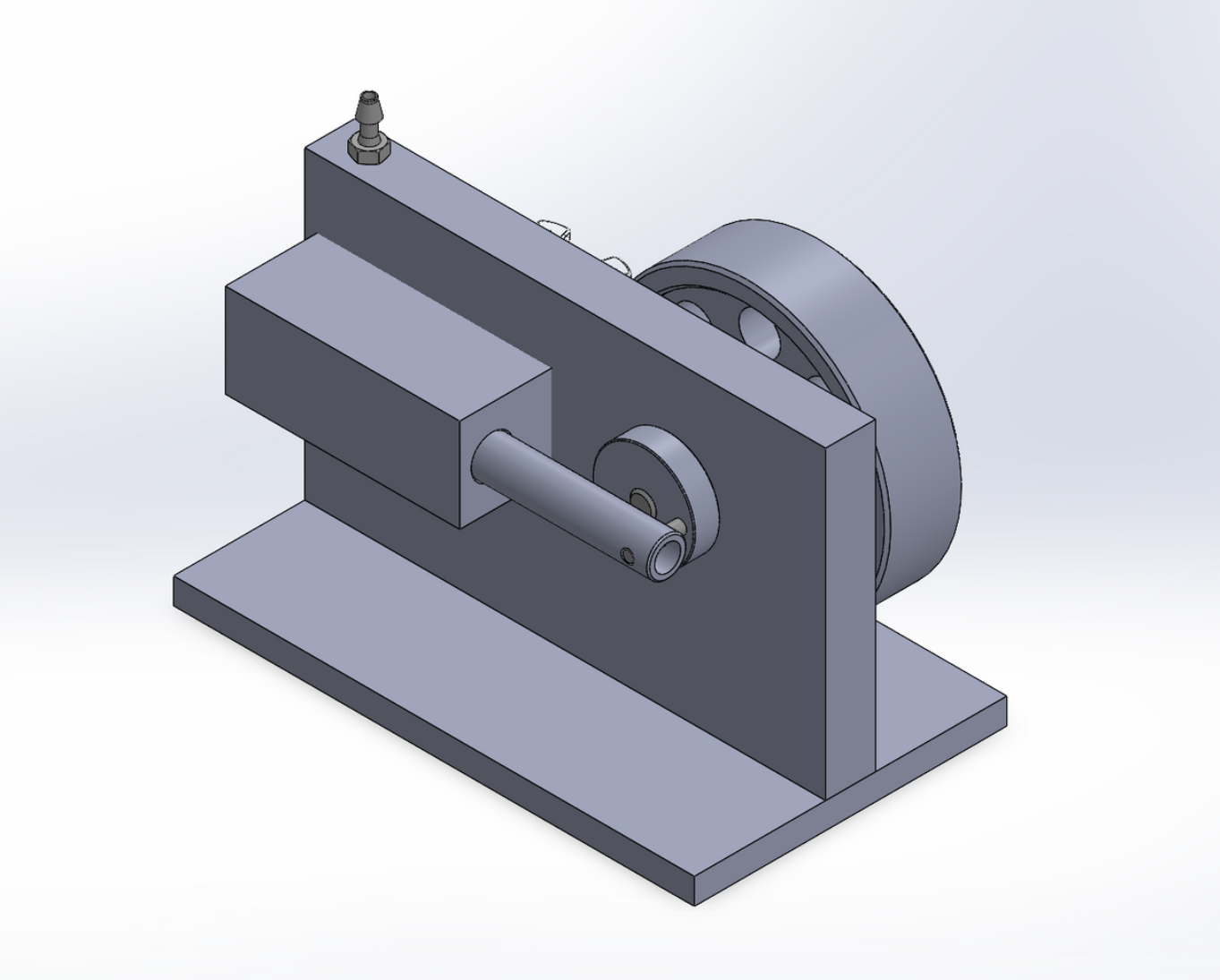

Figure (1) on the right showcases a completed assembly model of what I was tasked to make.

Figure 1: Complete Wobbler Engine Model

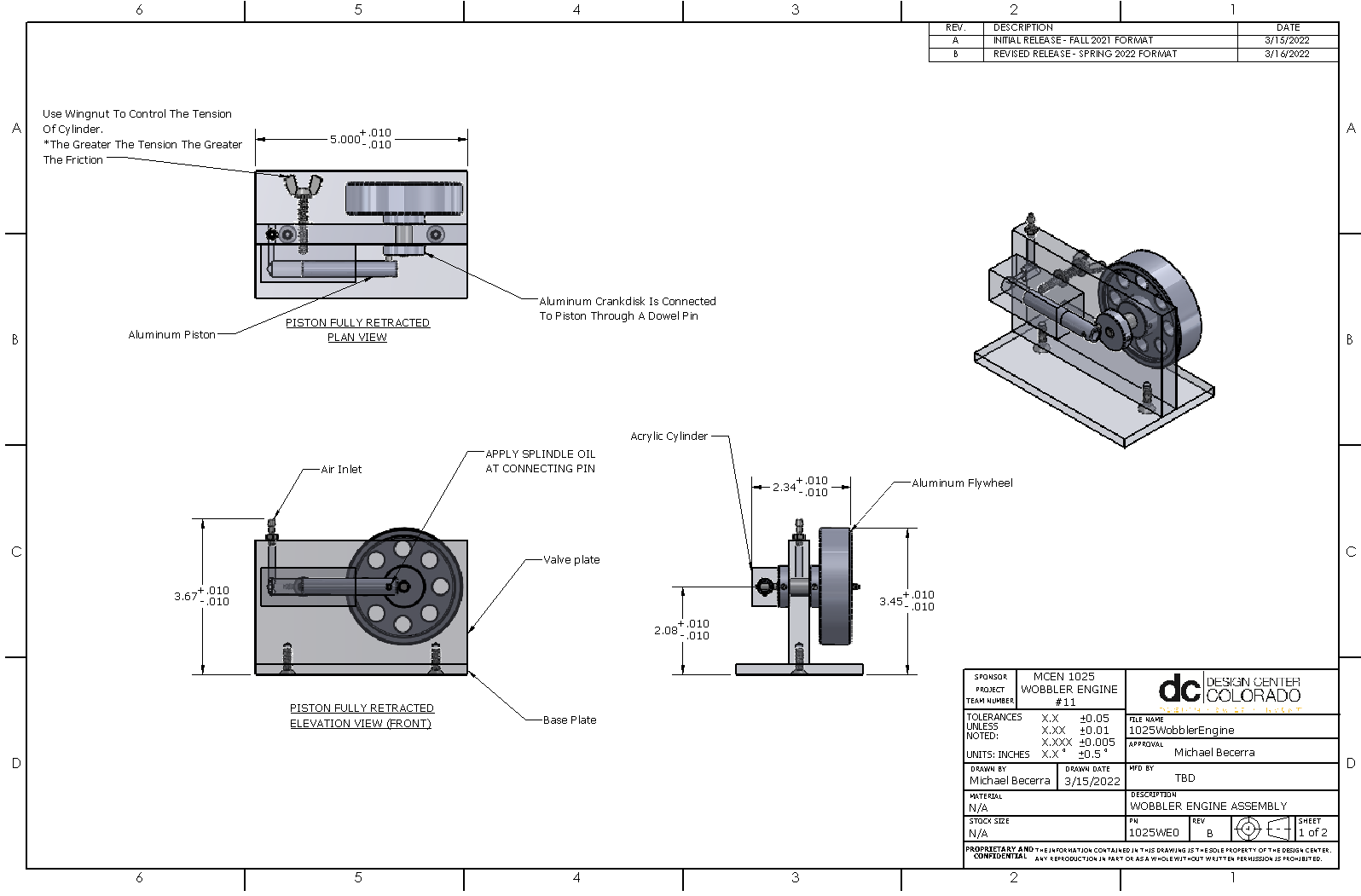

Before manufacturing, we were required to create a working SolidWorks assembly of the wobbler engine using reference drawings. This step demonstrated our ability to accurately draft and interpret engineering drawings into a 3D model.

Below is a list of the drawings I created for the wobbler engine.

Each component was modeled individually from these drawings and then assembled to create the final wobbler engine assembly, as shown in the images to the left. An animation demonstrating its functionality can also be viewed in the slide deck.

After completing the assembly, I created assembly drawings, including an exploded view of all components, as seen below.