For my SolidWorks course (MCEN 1025), I was given an assignment to recreate a real-life model of an object in SolidWorks with accurate dimensions. The goal of this project was to showcase what we had learned throughout the semester in SolidWorks.

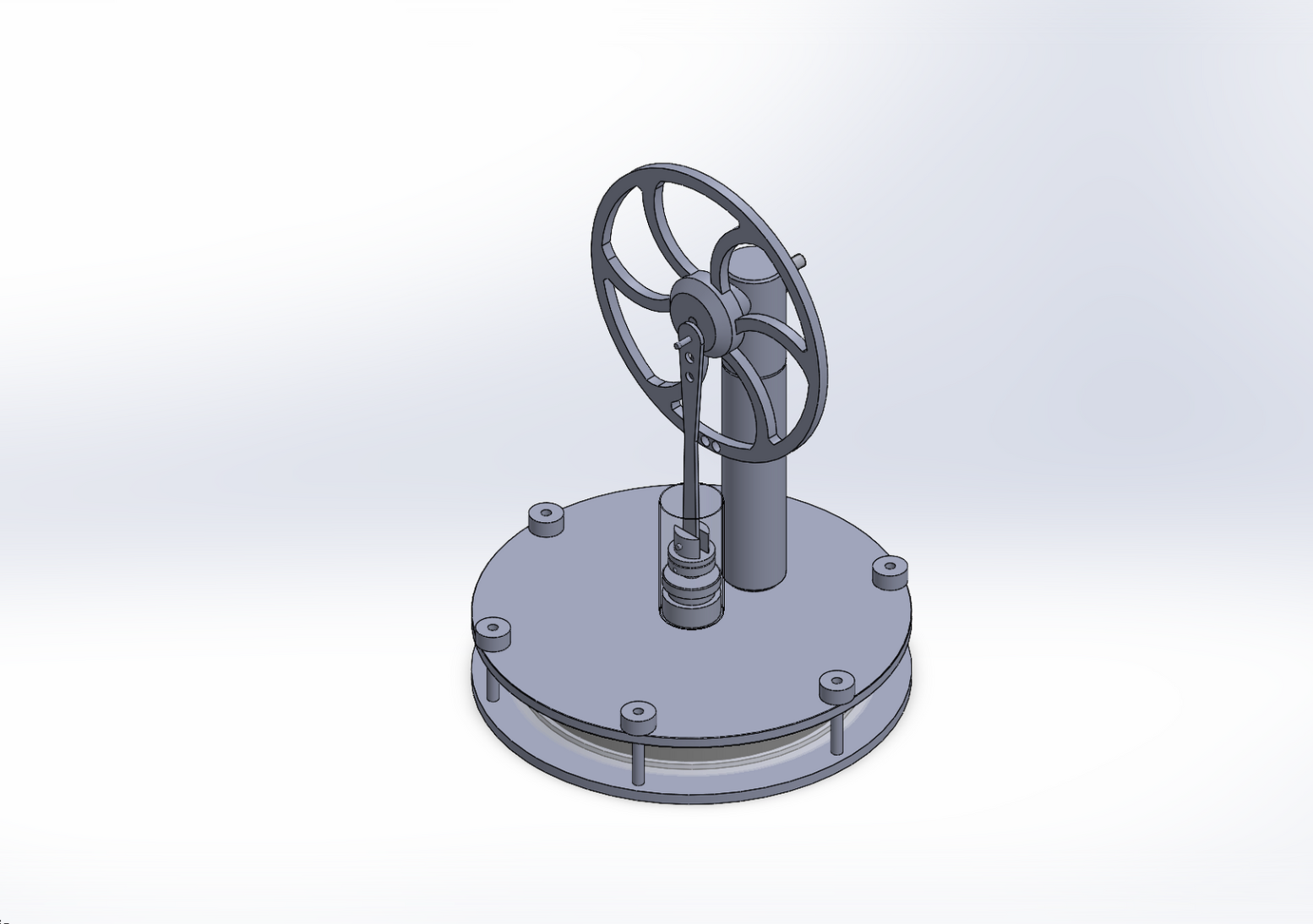

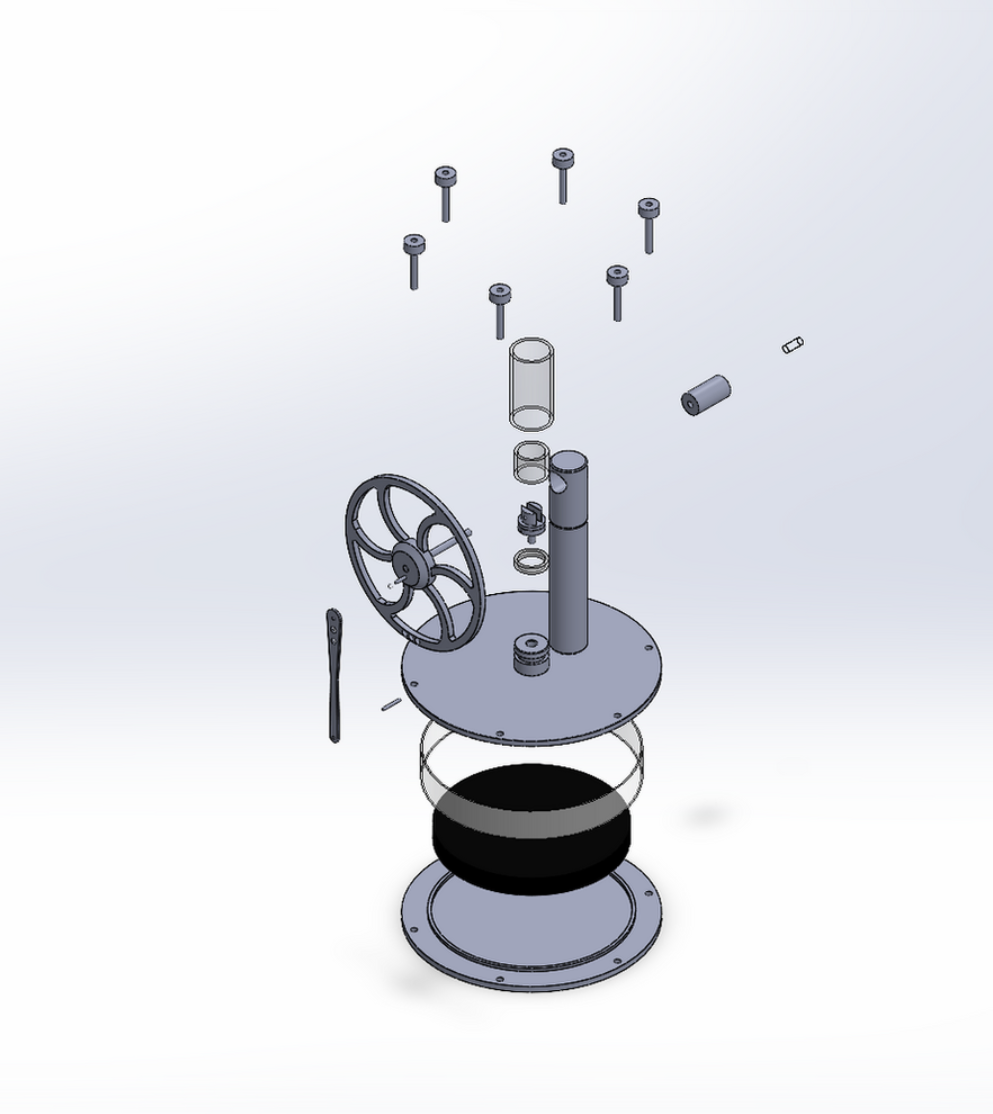

For my project, I chose to model a miniature Stirling engine and used calipers to capture the dimensions of each component.

For some background, a Stirling engine is a type of heat engine that converts heat energy into mechanical energy. It works by alternately heating and cooling a gas, which causes changes in its pressure that drive a piston. Unlike traditional internal combustion engines, the Stirling engine uses external heat sources, which means it can run on a variety of heat sources, including a coffee mug filled with hot liquid.

Two images of the Stirling engine I used can be seen in Figure (1).

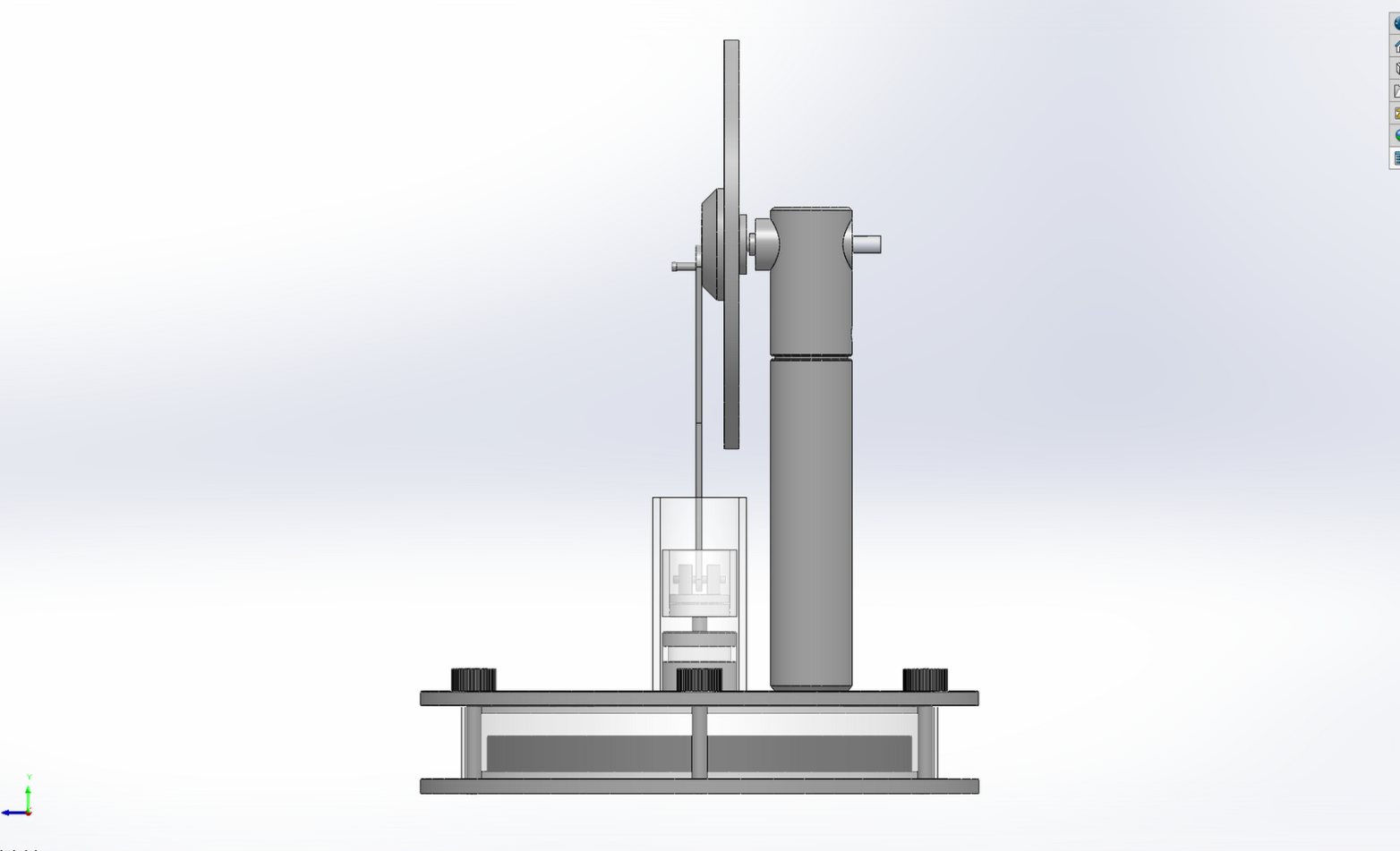

Once measurements were obtained, I began modeling each component before creating a final assembly that was fully mated. This can be seen in the next section below.

Figure 1: Real Minatare Stirling Engine